Excitement About Laser Scanning Solutions, Llc.

Table of ContentsThe Best Strategy To Use For Laser Scanning Solutions, Llc.Not known Details About Laser Scanning Solutions, Llc. Laser Scanning Solutions, Llc. - QuestionsThe smart Trick of Laser Scanning Solutions, Llc. That Nobody is Talking AboutThe smart Trick of Laser Scanning Solutions, Llc. That Nobody is Talking AboutLaser Scanning Solutions, Llc. for Beginners

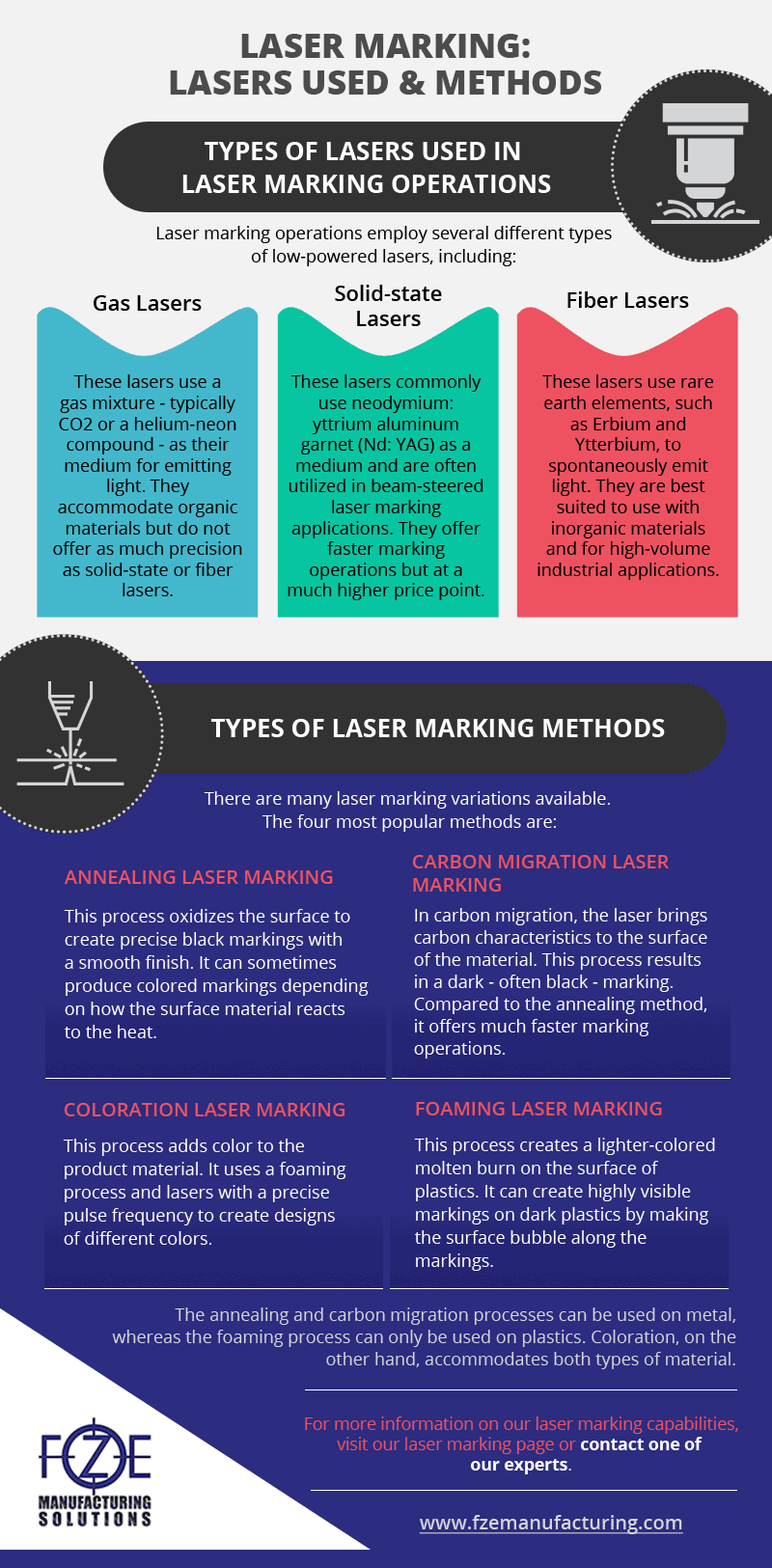

Lasers are almost everywhere around us (3d laser scanning services). Surgeons utilize them for eye surgical treatment and cancer therapies. Makers utilize them for material processing to cut, mark, weld, clean, and structure different types of materials. Some people need them for tattoo or hair elimination, and every person has actually seen laser light reveals during songs performances.Various types of lasers are required for these applications (https://www.pinterest.com/pin/984318062293812745/). Based upon their gain tool, lasers are categorized right into five major kinds: Furthermore, these 5 kinds of lasers can be divided into subcategories based on their modus operandi: continuous-wave lasers and pulsed lasers. There are also several types of pulsed lasers.

A laser is a tool that creates light in the kind of a laser beam of light. A laser beam of light is different from a beam in that its rays are single (a single color), systematic (of the exact same frequency and waveform), and parallelled (entering the same direction). Lasers supply this "best information" which is suitable for applications that require high precision.

Fascination About Laser Scanning Solutions, Llc.

It varies according to the type of laser. It can be a laser diode, an electrical discharge, a chemical reaction, a flash lamp, or also an additional laser.

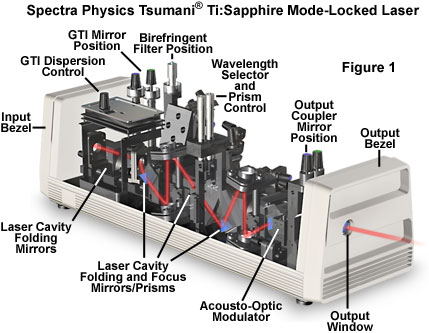

The intensifies the optical gain with mirrors that border the gain medium. These include mass mirrors in solid-state lasers, cleaved or coated aspects in laser diodes, and Bragg reflectors in fiber lasers. A gas laser is a laser in which an electric current is sent through a gas to generate light with a process recognized as populace inversion.

In fiber lasers, the gain medium is an optical fiber (silica glass) combined with a rare-earth aspect. The light guiding buildings of the fiber optics are what makes this kind of laser so different: the laser light beam is straighter and smaller than with other types of lasers, making it extra precise.

The Ultimate Guide To Laser Scanning Solutions, Llc.

, implying that the wavelength can be managed while in operation. Lasers are tuned to specific atomic vibrations.

They are then divided with an electric field, achieving what is called isotope separation. Laser diodes, additionally called diode lasers and semiconductor lasers, are comparable to regular diodes because they have a positively-negatively (PN) charged joint. The difference is that laser diodes have an innate layer at the PN junction made of products that produce spontaneous discharge.

A lot of semiconductor lasers are diode lasers, a few of them are not. Like fiber lasers, laser diodes can be categorized as solid-state lasers considering that their gain medium is solid.

4 Easy Facts About Laser Scanning Solutions, Llc. Explained

Laser diodes are usually made use of as power sources to pump other lasers. They are used in barcode readers, laser guidelines, laser printers, laser scanners, and numerous various other applications.

This is what we call their modus operandi. With, there is a consistent circulation of power, suggesting that the laser continually fires a solitary, uninterrupted laser beam. The most common example of this is a laser guideline's undisturbed light beam. Continuous-wave lasers are commonly used for laser cutting and laser welding.

Top Guidelines Of Laser Scanning Solutions, Llc.

For instance, a 6,000 W continuous-wave laser constantly releases 6,000 W of laser power. Alternatively, a 100W pulsed laser can launch pulses of 10,000 W each. Pulsed lasers are separated into a number of groups based upon the duration of their pulses. A modulator is made use of to control the number of pulses per second. Therefore, each pulse has an exact period, called pulse duration, pulse size, or pulse size.

( one millionth of a second) are probably the least common pulse durations They can be made use of for material handling applications, yet the complying with pulse periods are much more commonly utilized, as they offer a lot more precision. Microsecond lasers can likewise be used for applications like spectroscopy and hair removal. (one billionth of a second) are really usual pulse periods utilized for applications like laser material processing, range measurements, and remote noticing.

Unknown Facts About Laser Scanning Solutions, Llc.

( one trillionth of a 2nd) and (one quadrillionth of a second) are the shortest pulse periods, which is why the terms ultrashort pulses and ultrafast lasers are utilized. These lasers use one of the most precise results and have the lowest warm impacted areas. This stops unwanted melting and permits very precise engravings.

As you can see, there are lots of ways to categorize lasers. One more method is by the laser wavelength, where you have actually infrared, near-infrared, noticeable, ultraviolet, and X-ray lasers. Laser experts maintain pressing the restrictions of laser innovation, with new growths being made annually. Therefore, the kinds of lasers are regularly developing, and anyone aiming to explore this globe can expect a life time of explorations.